Robotic Systems

Robotic Systems

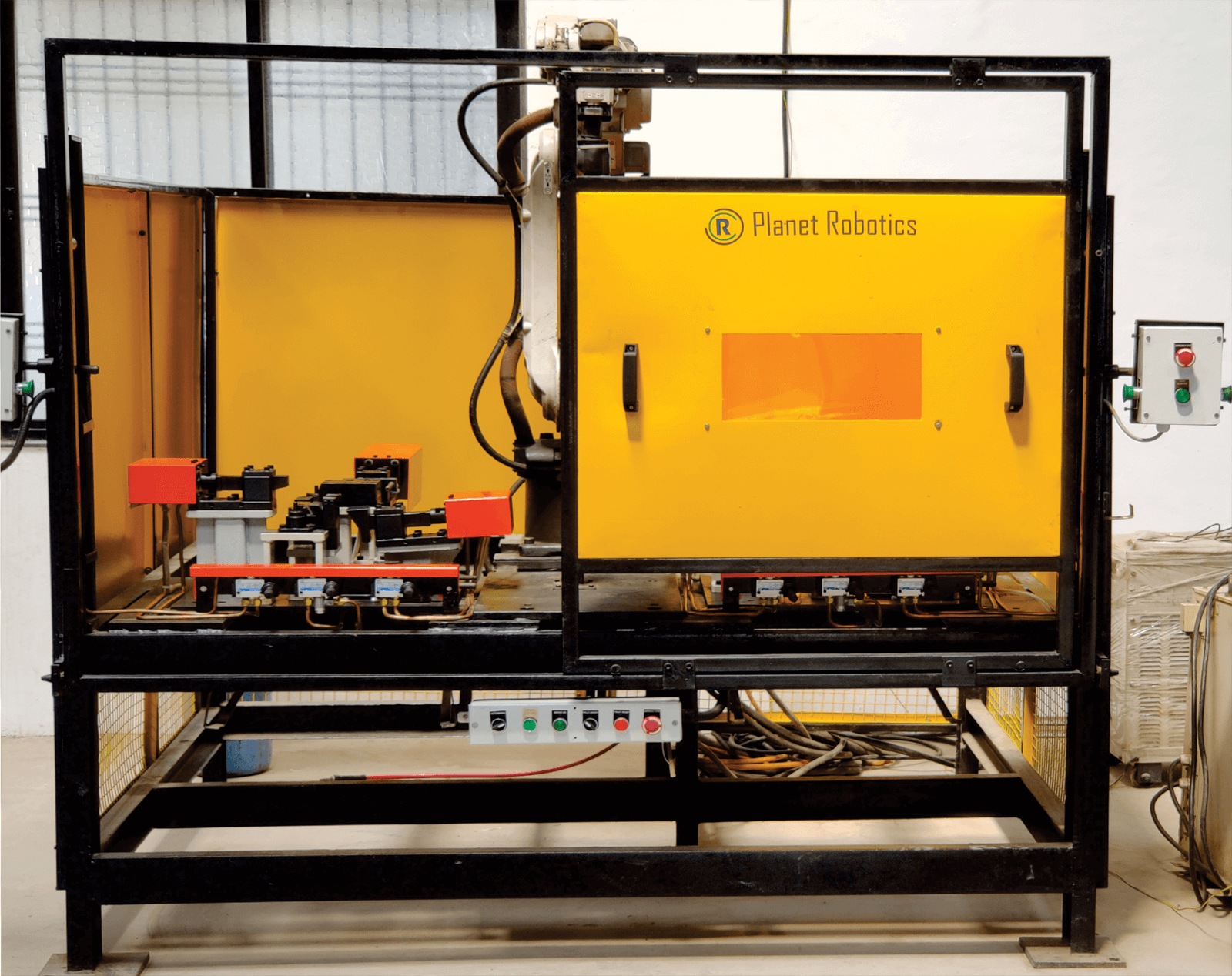

Planet Robotics systems are engineered to outperform competitive offerings, providing more flexibility, better workflows, and highly consistent productions.

Planet Robotics offers turnkey robot-based automation systems for a whole range of industries and applications including:

- Robotic Handling

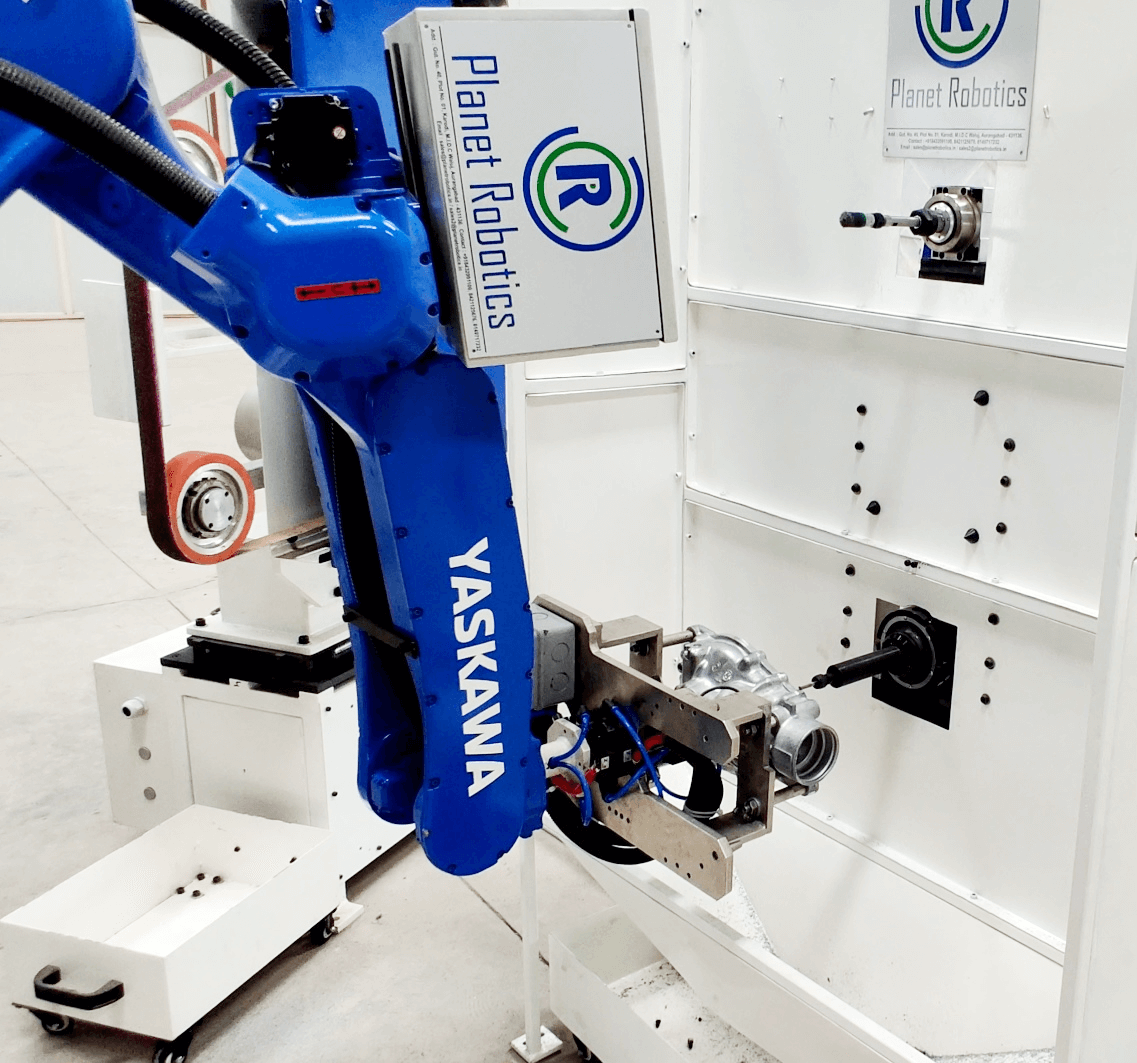

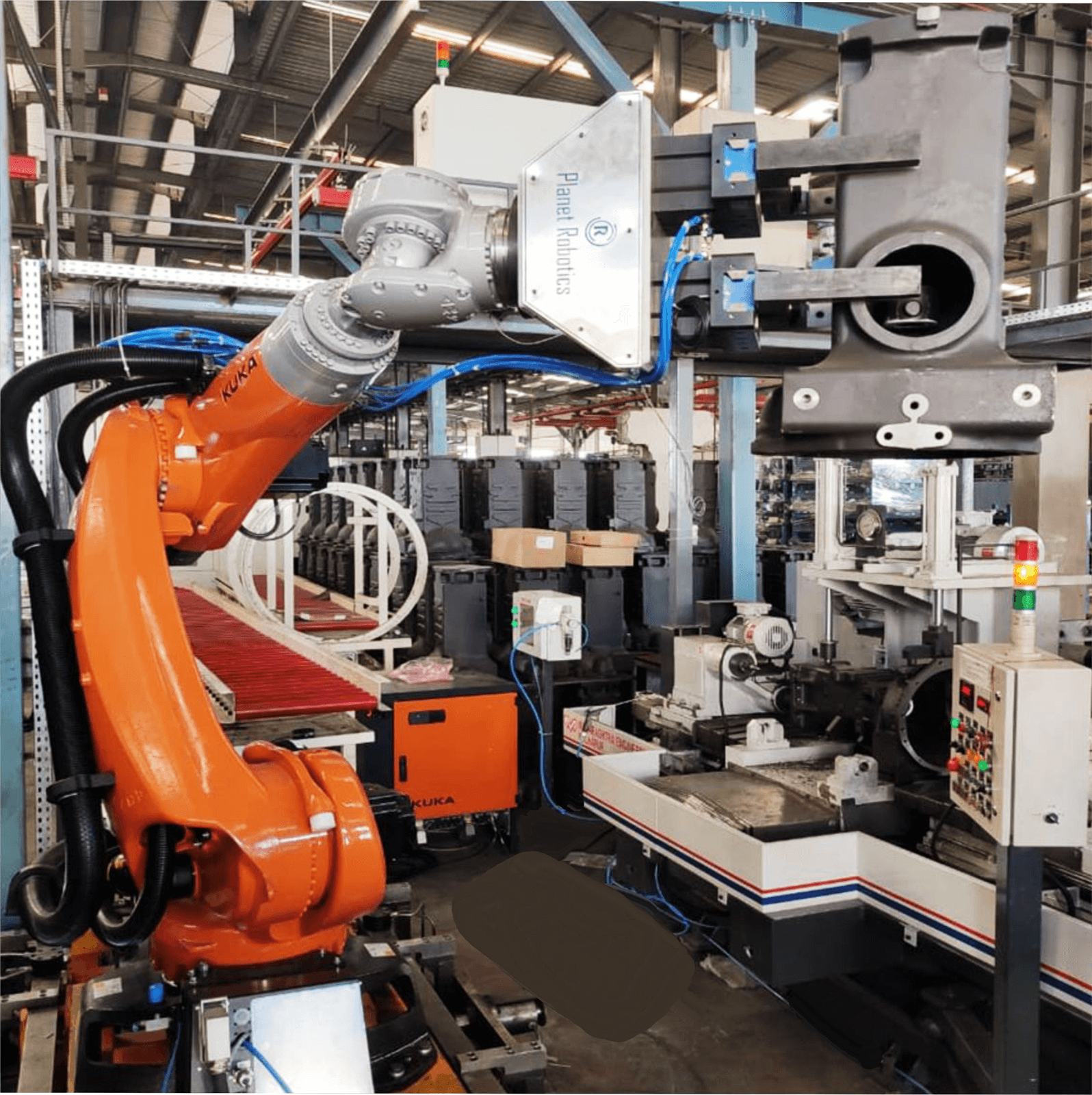

- Robotic CNC Tending

- High Pressure Die Casting Extraction

- Spray Painting

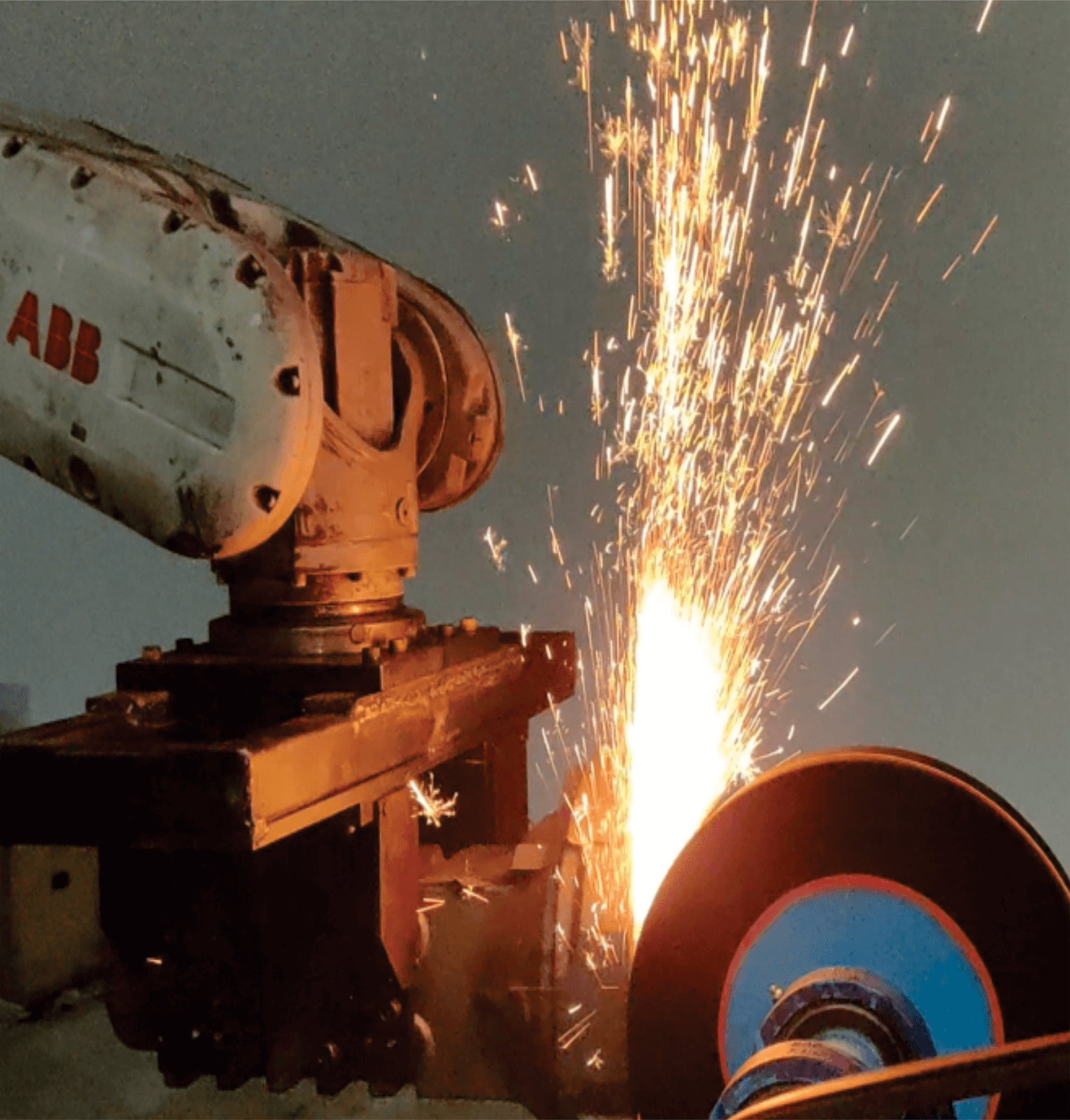

- Robotic Machining

- Sand core Deburring

- Aluminum Deflashing

- Metal Pouring

- Plastic Deflashing

- Gate/ Runner Cutting

- CI Fettling

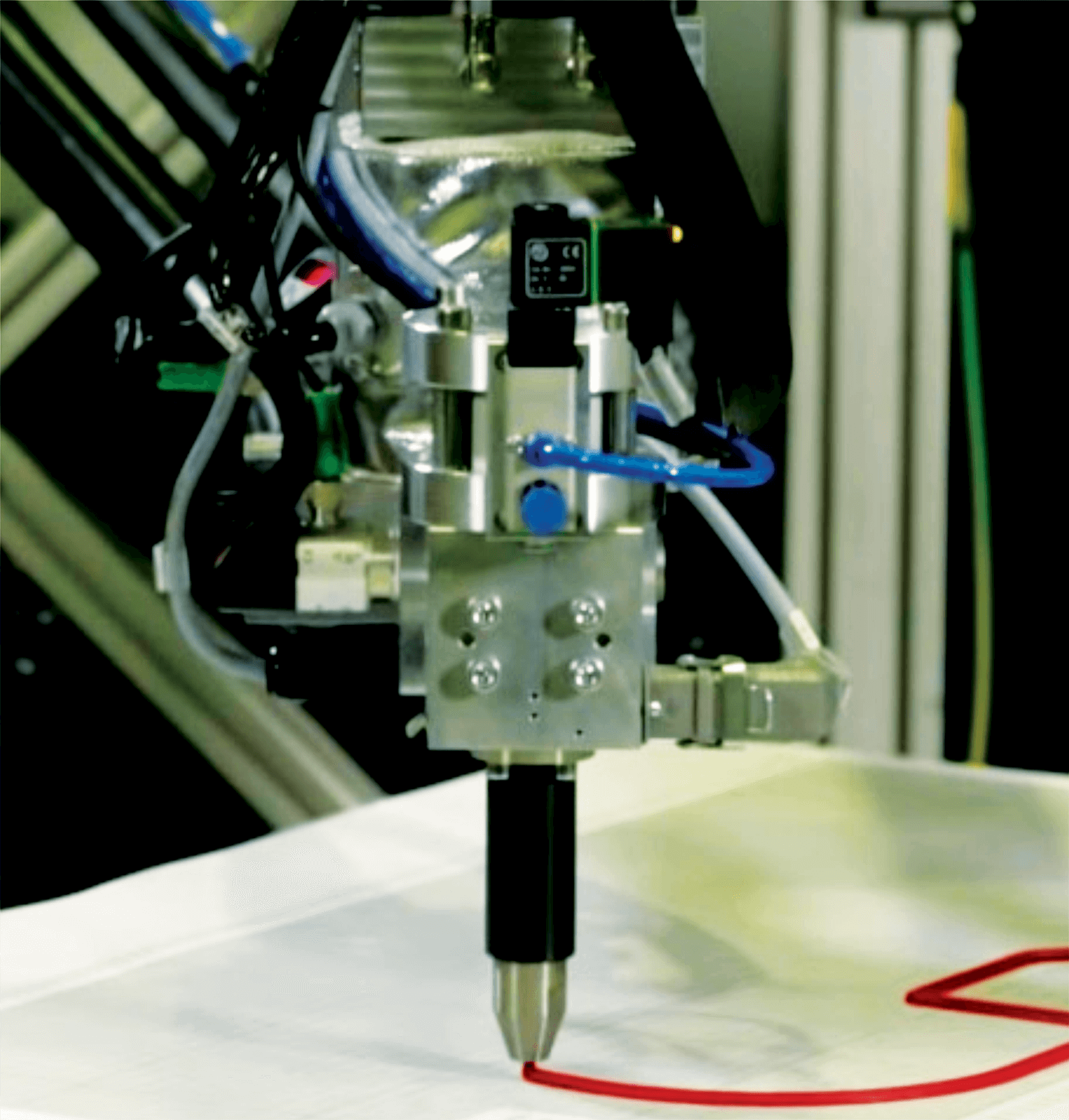

- Gluing

- Washing

- Foundry and Forge

- Arc Welding

- Assembly Applications

- Sealing, Waxing and Spraying

Our Products

Alluminium Deflashing

Planet Robotics offer the quality of castings needs to be good and the parting line flash thickness and length should be consistent. If there is consistency, robotic deburring can drastically improve the productivity and significantly reduce the dependence on labour. Inventory costs will also come down as the components can be delivered to customers faster.

Gluing Automation

The solution of a glue dispenser attached to the robot is also a good fit for the automotive industry, where a six-axis robot has the flexibility to glue over the rough edges of an automotive After this, adhesive bonding normally takes place, during which a robotic clamp attached with the other part.

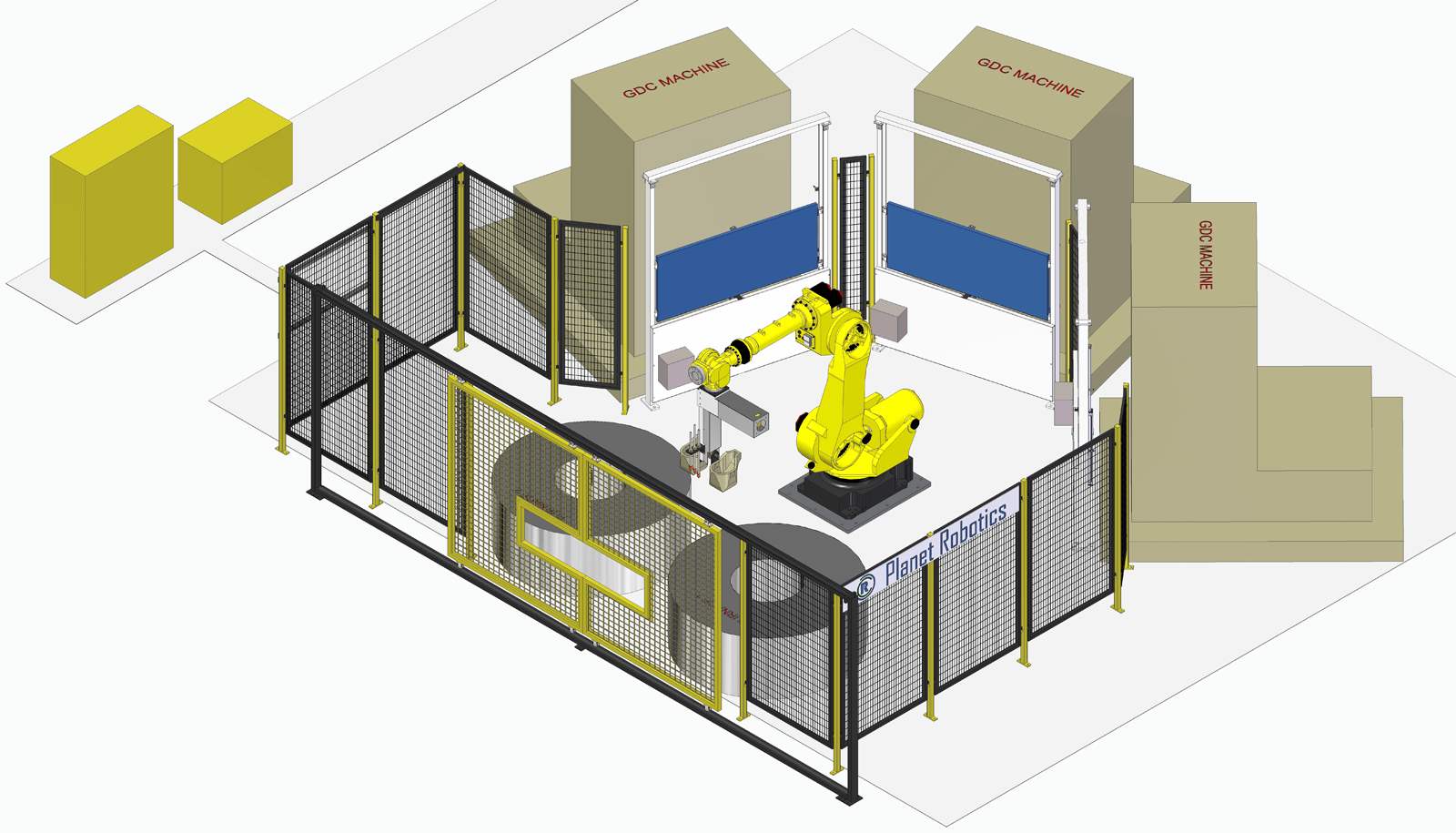

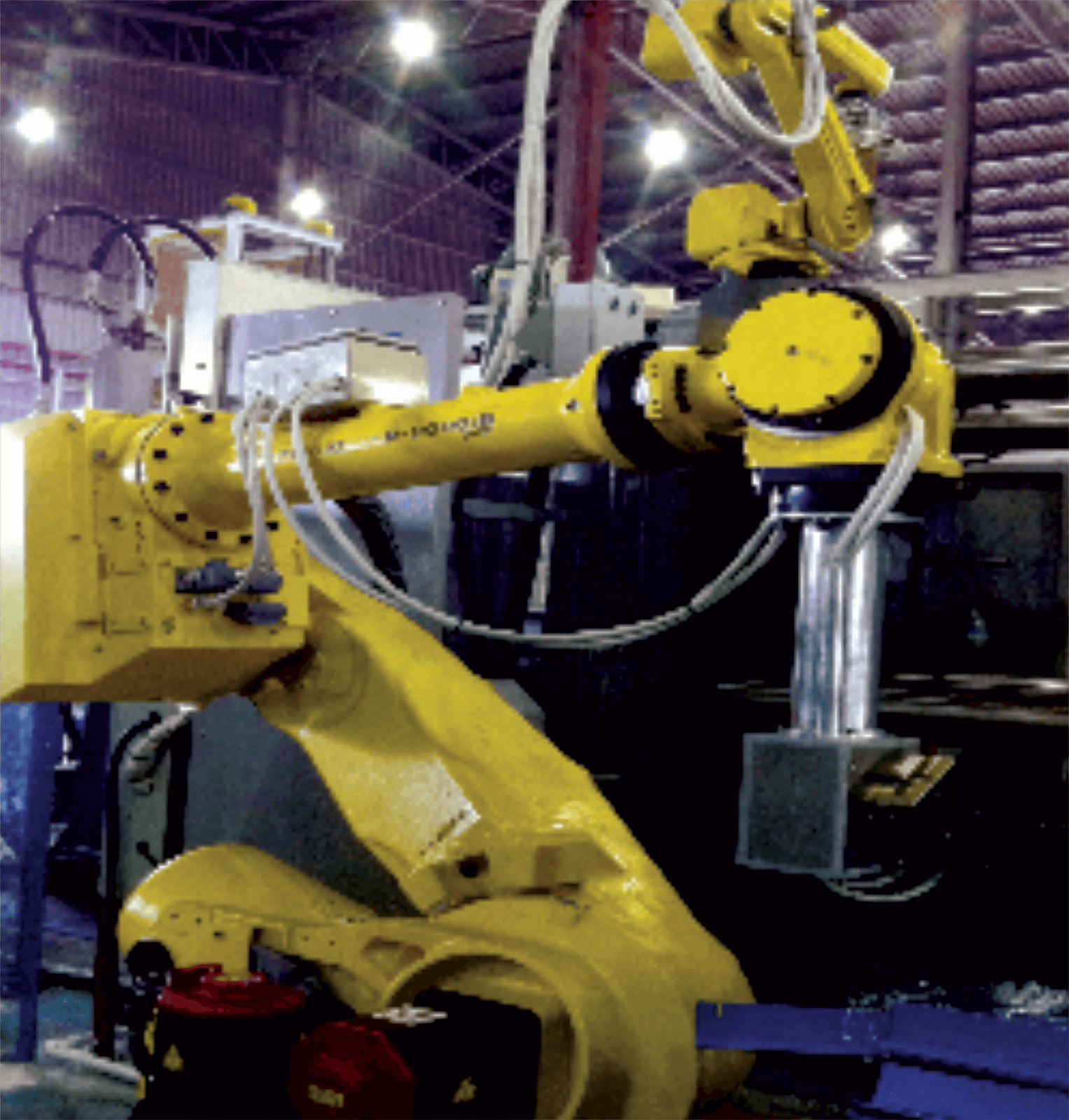

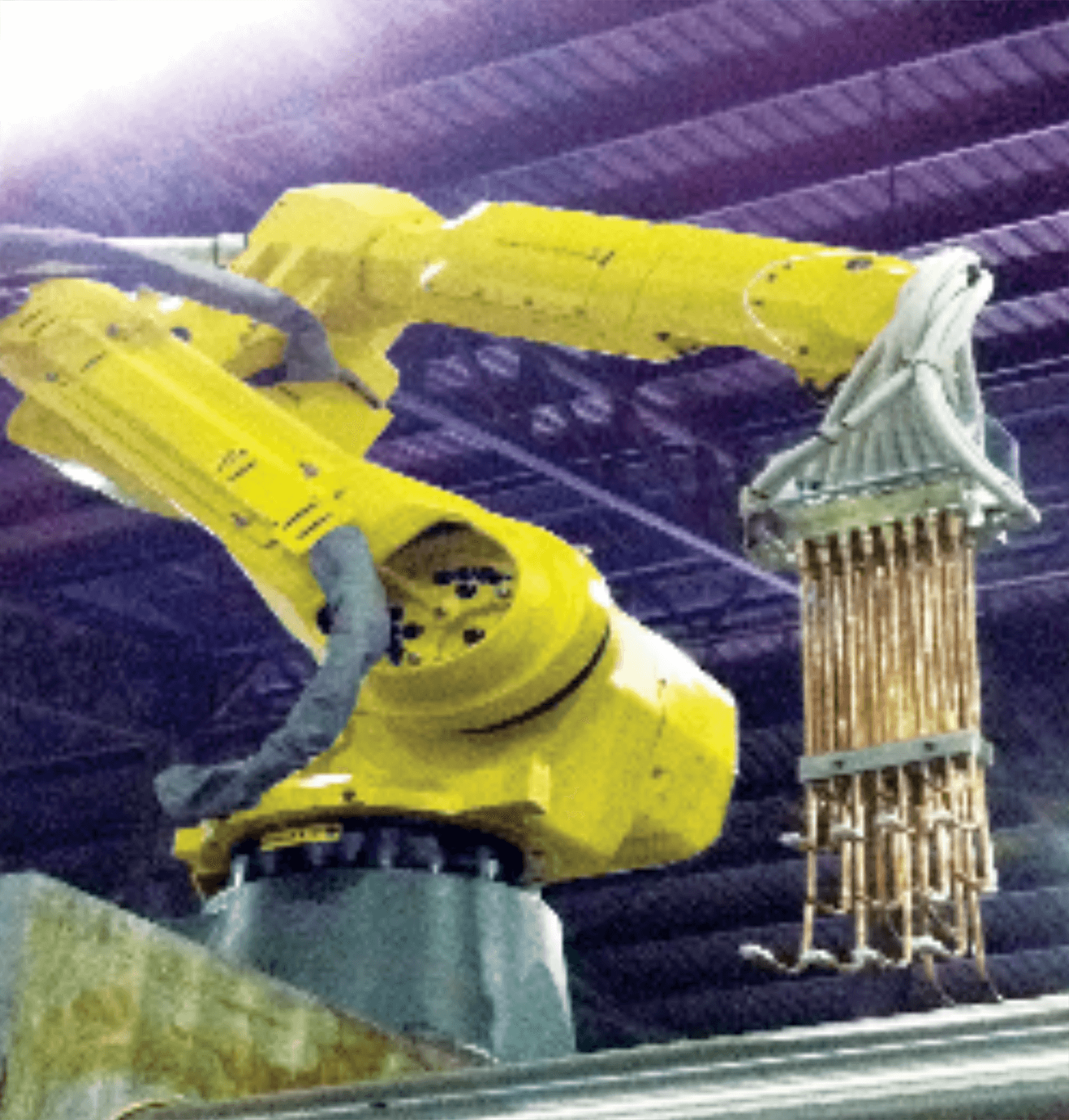

Robotic HPDC Extraction

To utilize the robot to its maximum potential by combining the extract process with additional tasks such as insert loading, spray or handling the casting through the cooling and trimming operations. Peripheral equipment including cooling racks, trim presses, conveyors, and safety fence can all be provided by Planet Robotics

Robotic Spraying

Robotic spraying systems with the shelf-mounted robots designed specially for operation on die-casting machines, even very large machines can be automated. The product range covers payloads from 16 to 270 kg and reaches of up to 3,900 mm. The foundation for process reliability and high performance during robot-based metal casting

Handling Automation

Planet Robotics offer Industrial automation solutions ranging from conveyors to industrial robots, gantry system and automated storage systems. We have the tools, knowledge and experienced professionals to evaluate your operation and determine perfect automated solution is right for you.

Welding Automation

Robotic welding automation uses robots to improve welding by increasing speed, producing quality welds and reducing errors. Integrating an industrial robot is easy and a great step toward improving a production line. Welding robots includes processes like arc welding, MIG welding, TIG welding, laser welding, spot welding, and more.

Robotic Spray Painting

Robotic painting and coating provides a wide range of advantages, includs Improved safety in hazardous painting work environments. Consistent robotic paint application significantly reduces material waste, higher product speeds and productivity, Increased painting system system uptime etc.